Pace of change in technology

The relationship between humans and machines

UK & Europe Director for Intelligent Mobility

Our world is changing faster than ever before, with technologies emerging that have the potential to revolutionise the way we live and work together.

However, there is a danger that technology advances so quickly that there is a disconnect with the people that it was designed for, says Caroline Paradise, Head of Design Research at Atkins: “It’s important to remember the human aspect of design – how the user fits into this changing world and how they engage with and use the technology. As consumers of the built environment and infrastructure, people are central to this.”

All this new technology has to fit in with existing infrastructure, she adds. “We need to think about how new technology interfaces with the world we currently live in as well as a future state.”

To this end, Atkins has just taken on a cyborg ethnographer, to study and explain to clients the relationship between humans and machines. “We hope to reinforce the importance of the relationship between humans and assets,” says Nathan Marsh, Atkins’ UK & Europe Director for Intelligent Mobility.

“I worry that people are building the most advanced technology and not dedicating enough time to really understanding the human-related implications of robotics and automation,” he adds. “Human acceptance of next-generation technology is key.”

The wider consequences of individual technological developments are not always thought through, he adds: “Autonomous vehicles are really, really smart, but that is just the tip of the iceberg. When entire vehicle fleets are autonomous, it could challenge the need for all sorts of things we accept as normal, such as bus stops, car parks, personal insurance, or even driving lessons.”

The factors that may limit the spread of technology are not always obvious, either. “The big challenge for autonomous vehicles might not just be in the technology – it will be whether we have enough fast and reliable Wi-Fi connectivity to keep vehicle networks running and safe,” says Marsh. “Also, will we have enough server space? One state-of-the-art autonomous car running for 15 minutes generates as much data as the Large Hadron Collider, and we need to model in what 100,000–200,000 of these vehicles will need, and generate, to keep us confident that we are ready for them. Server space and Wi-Fi are not going to make headlines, but they’re absolutely crucial parts of technology acceptance.”

Despite these potential barriers, digital is offering clear benefits when it comes to asset management, by combining with other technologies to improve the way we design, build, operate and maintain physical assets. For example, components that need replacing can now be 3D printed directly from a 3D digital model, and we can create a “digital twin” of an aircraft that acts both as a blueprint for the particular type of plane and a record of the life of an individual aircraft, and that tracks any modifications over the duration of its operational life.

Find out more about Intelligent Mobility

VISIT OUR iM HUB“We can monitor the performance of an entire fleet, manage the maintenance schedule much better, predict how damaging each flight is and know the status of an aircraft without having to inspect it manually. This means we can manage its performance much better,” says Andrew Munday, Head of Advanced Engineering at Atkins’ Aerospace, Defence, Security & Technology division. “Ultimately, it enables you to make much quicker and better decisions about the management of assets.”

The pace of change has been so rapid in part because “the advance in processing power is happening at almost breakneck speed,” says Marsh. This opens up new possibilities; for example, the use of artificial intelligence to rapidly make precise judgements that previously would have taken much longer, or would have required a certain amount of guesswork.

Other technologies and techniques allow engineers to approach product design in a completely different way. Topology optimisation, for example, inputs the parameters and constraints of a product into a programme that then comes up with the most efficient design, rather than the previous method of looking at what the product needed to do and coming up with a best guess of what it should look like.

This method has been enhanced by new design freedoms created by the advent of 3D printing or additive manufacturing. Because the process starts with nothing and prints products layer-by-layer, it is possible to create shapes that are not possible when using the traditional technique of taking a lump of metal (or plastic or other material) and taking bits away. For example, components can be made that are mostly hollow, and therefore much lighter but still as strong as their solid predecessors.

The development of new advanced composite materials is reducing the weight and increasing the life of components. Further, because composites are created layer-by-layer, sensors can be embedded within them for through-life monitoring. In the future, substances such as graphene, which is conductive, could in some cases remove the need for separate sensors altogether. Then there are the changes in the energy sector, which is moving from a fossil fuel-powered world towards greater use of electrical power and renewable energy, as well as a shift to greater autonomy in vehicles. These trends are complementary – it is much easier to make an autonomous electric vehicle than one powered by internal combustion. “Electric propulsion is much more suited to the digital age,” says Munday. And even when vehicles are not being propelled by electricity, it is still playing a greater role – in aircraft, for example, where electric systems are replacing many hydraulic, mechanical and air systems.

All these technological developments have changed what is possible more quickly than regulators, designers, engineers, individual companies and in some cases entire industries can keep up with. “We operate in industries that are quite heavily regulated,” explains Munday. “It is regulations and people’s mindsets that are holding up the pace of change, not the technology.”

Sometimes there is a lack of confidence about adopting new technology, and designers steeped in a particular way of thinking struggle to adapt to the new possibilities. Using additive manufacturing as an example, Munday adds “It can be difficult when you have spent your entire working life designing from the outside in to suddenly change to designing from the inside out.

Then there is the risk for companies, particularly large corporations, that are so invested in a particular technology that they cannot move on. A wide range of sectors, face the danger that they end up competing with the wrong people – car makers may focus on their rivalry with other vehicle manufacturers, while their new rivals could actually be Google, Uber and Apple.

The same risks apply to knowledge-based companies such as Atkins, whose main asset is their expertise.

Here, there is a risk that progress will be held back by a skills gap, which we explore in the next chapter of the report, but equally this is an opportunity for Atkins to leverage the fact that it can offer both engineering and IT expertise in a way that is closely aligned. And while many lower-skilled tasks may become redundant, the need for high-end skills and analysis will only grow.

The advent of digitalisation has created an extremely powerful set of tools that engineers can access, but they are still trying to achieve the same things, Munday says: “It’s all about the outcome, about solving problems. Digital just allows us to do it better, and more quickly.”

Concepts such as the digital twin have even created a new asset class for investors, says Marsh: “Conventional infrastructure is a very established and pretty secure asset class. Digital infrastructure, particularly digital twins of transport infrastructure, is a new asset class, and as yet unproven and unrated at scale. Whilst they have completely different risk profiles, both have a value to users and investors. Thinking ahead, I think they are different sides of the same (bit)coin.”

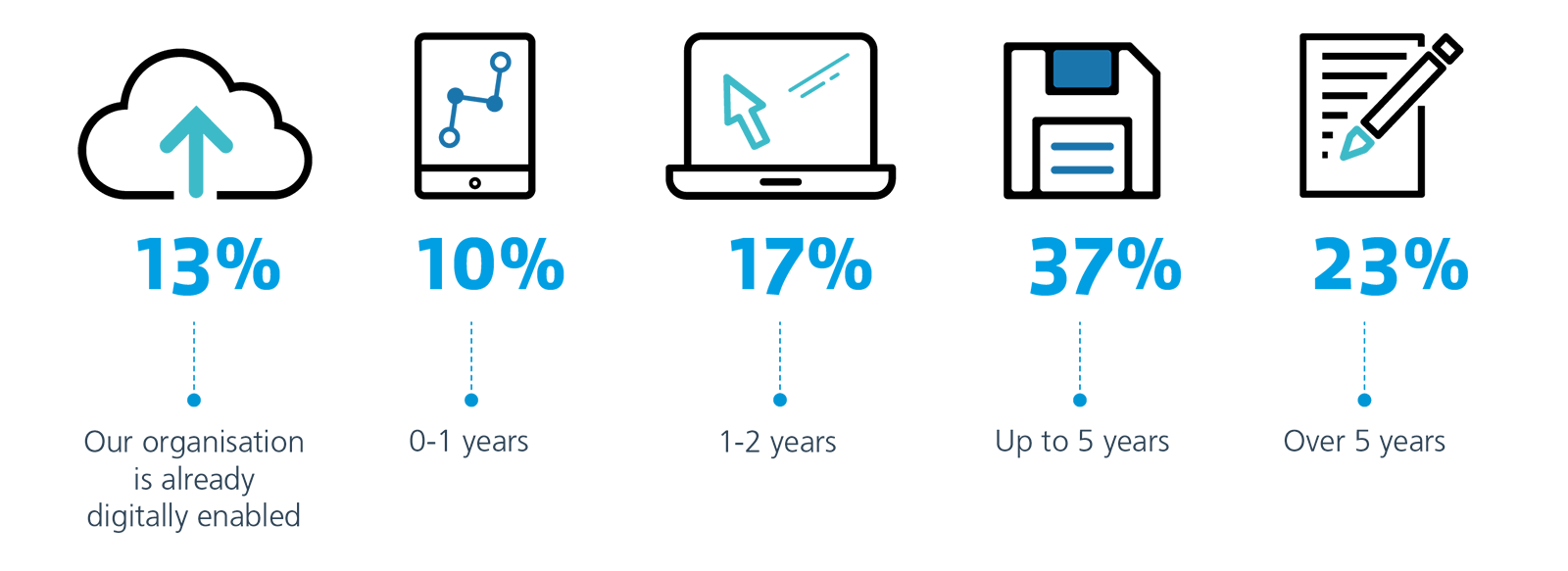

How likely is it that your company will make funding available for digital investments in the future?

-

The biggest challenge is that the technologies are changing so fast that by the time you implement one, the next one is already there.

Anton KoekemoerDirector at Boogertman and Partners Architects

Anton KoekemoerDirector at Boogertman and Partners Architects